Full Tour: Zipline Factory & HQ

$7.6B Valuation | CEO Keller Rinaudo Cliffton

Full Zipline Factory & HQ Tour

CEO Keller Rinaudo Cliffton gives us a rare BTS tour inside Zipline’s factory + HQ powering the world’s largest autonomous delivery system.

Zipline runs a fully vertically integrated delivery system spanning hardware, autonomy software, fleet operations, Dock/Droid last-mile logistics, & customer ordering

Keller takes us through end-to-end from live global flight ops in the ROCC to walking the production line for aircraft & Droid manufacturing.

We cover hardware-in-the-loop simulation, Dock infrastructure, autonomy & engineering teams, reliability stress testing, and the consumer app powering on-demand delivery at scale.

This was really fun, I hope you enjoy!

→ Listen on X, Spotify, YouTube, Apple

DISCLAIMER: This is a LIVE factory, it is a bit noisy and audio can be inconsistent at times. Hope you enjoy :)

𝐓𝐈𝐌𝐄𝐒𝐓𝐀𝐌𝐏𝐒

(00:00) Inside Zipline HQ

(04:16) The ROCC: Remote Operating Command Center

(06:29) Watching live takeoffs, routes, and landings

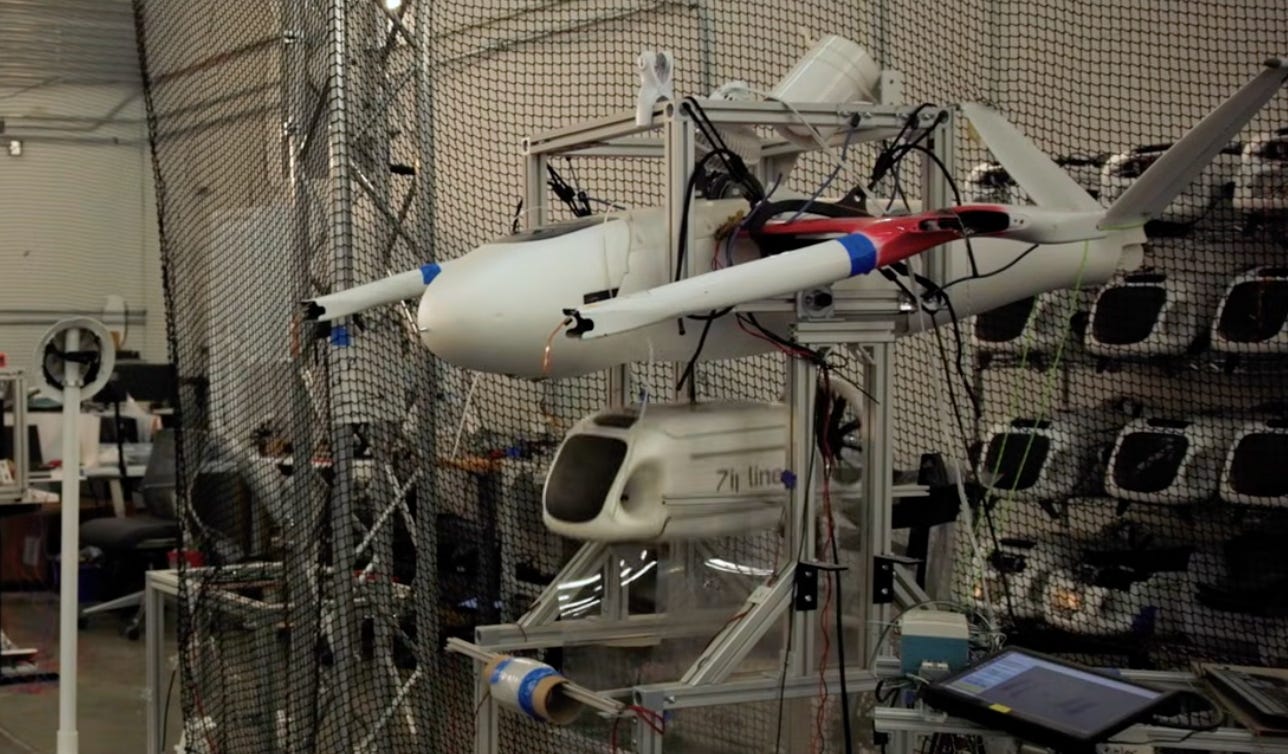

(09:31) HITL testing & avionics stack: BMS, antennas, flight compute, motors, controllers

(12:41) Inside Zipline’s manufacturing line and aircraft structure

(14:00) From 43 sub-assemblies & 700+ components to flight-ready aircraft

(17:43) Zipline’s dock system explained: docking, charging, & making autonomy feel human

(22:50) Stress testing autonomy before the real world: Droid lifecycle testing

(24:02) Precision delivery to homes and backyards through the Zipline app

(26:59) Live accelerated stress testing in the vibration lab (The Vib Lab)

(34:13) Testing the RC fans (with my face)

Global Scale & Rapid Growth

Zipline is nearing 2,000,000 total deliveries and operates what Keller describes as a global system where “every one of those aircraft is out making delivery somewhere in the world.” The company says it has achieved 125 million commercial autonomous miles with zero safety incident, and it’s scaling fast: ~15% week-over-week growth, with operations running ~17 hours/day today and moving toward 24/7.

Zipline also highlights accelerating network effects in newer metros: some U.S. sites have scaled from launch to 100 deliveries/day in ~2 days, compared to ~110 days for earlier sites. In select cities, Zipline reports 50%+ of homes placing orders, and demand is currently supply-constrained as the system continues expanding.

Vertical Integration & Tesla-Inspired Operating Model

Zipline operates with a fully vertically integrated model that treats manufacturing, software, and operations as core products, not outsourced functions. Rather than relying on third-party aerospace suppliers or factory software, Zipline builds and controls its entire operating stack — from aircraft systems and autonomy software to manufacturing workflows, fleet orchestration, and internal logistics tooling.

Keller explains that this approach was shaped in part by Tesla’s manufacturing philosophy, especially the decision to colocate engineering and production so iteration loops remain fast and tightly coupled. Zipline’s HQ and factory function as a single system, allowing engineers to deploy design changes directly into production, shorten feedback cycles, reduce supplier dependencies, and lower cost per unit over time.

A key differentiator is Zipline’s custom-built manufacturing operating system, which manages production sequencing, component traceability, quality control, maintenance history, and supplier performance at the part level. This gives Zipline full lifecycle visibility for every component in every aircraft, enabling faster root-cause analysis, targeted remediation, tighter quality enforcement, and more reliable long-term scaling.

This end-to-end control allows Zipline to iterate faster, reduce cost, maintain reliability at scale, and operate independently of fragmented vendor ecosystems — mirroring Tesla’s view that manufacturing itself is a competitive advantage, not a downstream execution layer.

The ROCC (Remote Operating Command Center)

Inside the ROCC, Keller walks through how Zipline manages fleet oversight at scale, including FAA approval to fly at ratios of “one human to 30 aircraft” (and pushing beyond that).

Zipline tracks uptime, fleet performance, delivery volume, site ramp speed, and live aircraft telemetry across metros. Some sites scale from 0 to 100 deliveries/day in ~2 days, compared to ~110 days at its first Dallas site. In select cities, Zipline reports 50%+ of homes placing orders, and the system is growing at approximately 15% week-over-week. Operations currently run ~17 hours/day, with a transition toward 24/7.

The ROCC also provides real-time live monitoring of active deliveries, including aircraft routing, takeoff, landing, docking, and inbound/outbound package flow across U.S. sites.

Engineering & Technical Teams

Zipline’s HQ houses its core engineering organizations across autonomy, machine learning, detect-and-avoid, computer vision, powertrain, embedded systems, electrical engineering, mechanical engineering, safety & reliability, systems testing, and industrialization. The company employs ~1,300 people globally, including ~800 in the U.S., with more than half of the workforce in engineering roles.

The autonomy organization builds perception, navigation, routing, and collision-avoidance systems for both the aircraft (“Zip”) and the last-mile delivery robot (“Droid”), including computer vision, detect-and-avoid, and real-time flight intelligence.

Zipline runs a major global software update every six weeks, typically shipping ~60 bug fixes and ~25–30 performance improvements per release. Updates are validated through simulation, hardware-in-the-loop testing, and live flight testing before being deployed over-the-air across the full fleet, enabling rapid iteration while maintaining safety and reliability at scale.

Manufacturing Floor: Aircraft Production, Components, & Vertical Integration

Zipline’s factory builds aircraft with ~43 major sub-assemblies and ~700 unique components per aircraft. Core systems — including electric motors, battery packs, power distribution boards, flight computers, and manufacturing software — are designed in-house, following a Tesla-inspired vertical integration model.

The production line includes carbon-fiber structural molding, avionics installation, battery welding, dock manufacturing, and end-of-line test jigs. Zipline also runs accelerated lifecycle testing, vibration testing, temperature shock testing, and stress simulations to ensure durability before deployment.

The company maintains full component traceability, enabling batch-level quality tracking, warranty controls, supplier audits, and long-term reliability optimization across its fleet.

Reliability, Safety & Testing Infrastructure

Zipline emphasizes reliability as a core competitive moat. The company runs accelerated lifecycle testing, thermal stress testing, vibration tables, failure-forcing experiments, and hardware torture tests designed to ensure components fail in the lab rather than in the real world.

Through its HITL (Hardware-In-The-Loop) system, Zipline simulates tens of thousands of flights on real avionics before deploying software updates to live aircraft — helping catch the majority of bugs before real-world rollout.

Dock + Droid: Last-Mile Delivery System

The tour also covers Zipline’s Dock and Droid systems, which handle charging, data transfer, package handoff, telemetry uploads, and home delivery. The Dock preconditions aircraft, charges batteries, and uploads flight data, while the Droid manages precise home drop-off and positioning.

Zipline emphasizes quiet flight, safety, and public comfort, designing the system to feel less intrusive than traditional drone delivery — including a focus on low noise, friendly industrial design, and household-safe last-mile interactions.

Customer Experience & Product Layer

Keller also walks through Zipline’s consumer ordering experience, including the Zipline app, partner integrations (retail, food, and healthcare), and the ability for customers to select exact drop-off locations using satellite imagery — including backyards, driveways, poolsides, and doorsteps.

Zipline highlights high repeat usage, organic social sharing, birthday deliveries, and strong viral growth — contributing to demand that currently exceeds available supply in some markets.

Zipline 24/7 Livestream?

One unexpected outcome of Zipline’s expansion is that people now show up just to watch it operate. Keller mentions families driving to Zipline sites, sitting in parking lots, and treating takeoffs and landings like a local attraction. Kids ask to visit Zipline the same way they might ask to go to a park or museum.

Deliveries — especially birthday orders — have become shareable moments. Videos constantly go viral on TikTok (so much so that they cut their marketing budget due to all the demand created from it). People film aircraft coming in, the Droid lowering packages, and the system cycling through flights.

At this point, Zipline could plausibly run a 24/7 live feed of takeoffs and landings — a simple public stream of real-time operations — and it would likely attract a steady audience.

FWIW: When people go out of their way to watch your infrastructure run, it’s a signal that the technology has moved beyond novelty and into everyday culture.

Watch our full sit-down interview with Keller for more information behind their latest $7.6B valuation & financing round. → Listen on X, Spotify, YouTube, Apple

Brought to you by:

Brex—The intelligent finance platform: cards, expenses, travel, bill pay, banking—wrapped into a high-performance stack. Built for scale. Trusted by teams that move fast.

As a Sourcery subscriber you get: 75,000 points after spending $3,000 on Brex card(s), white-glove onboarding, $5,000 in AWS credits, $2,500 in OpenAI credits, & access to $180k+ in SaaS discounts. On top of $500 toward Brex travel, $300 in cashback, plus exclusive perks (like billboards..) visit → brex.com/sourcery

Turing—Turing delivers top-tier talent, data, and tools to help AI labs improve model performance, and enable enterprises to turn those models into powerful, production-ready systems. Visit: turing.com/sourcery

Deel—Deel is the global people platform that helps startups hire, manage, pay, and equip anyone, anywhere. Trusted by more than 35,000 fast-growing companies, Deel is the people platform that just works, so teams can scale without the chaos. Visit: deel.com/sourcery

Public-–Investing platform Public just launched Generated Assets, which lets you turn any idea into an investable index with AI. Seriously, you can type in anything, from “AI-powered supply-chain companies with positive free cash flow” to “defense tech companies growing revenue over 25% year-over-year.” With Generated Assets, you can build, backtest, refine, and invest in any thesis with AI. Gone are the days of one-size-fits-all ETFs. Try it today: public.com/sourcery